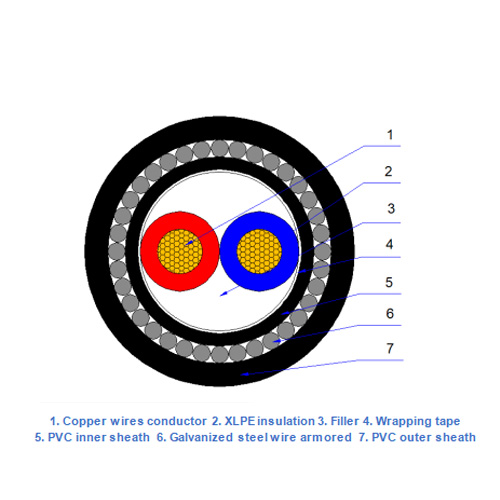

For single core armoured cable, the armouring beneath the sheath is usually Aluminium (AWA Cable). In cable with multiple cores, it is steel, SWA– Steel wire armour.

2 core 35 mm² SWA armoured cable matches both outside use and direct burial. The armour below the sheath also permits pulling loads because of increased strength.Use Cable Cleats to attach the SWA cable to walls and structures. Cable cleats give a safe, secure match. Cleats may also be a choice for running cable along the sides of the building, rooftops or outbuildings. Cleats provide safety and security for surface mounting.

You must utilize Warning Tape for underground cable positioning. Utilize warning tape offers cables to be visible in case someone was to dig in the area. Always treat safety as critical when you lay cables. Precaution tape reduces the high risk of accidental severing.

2 core 35 mm² SWA armoured cable have many advantages, as follows:

(1). Protects against physical damage — Armoured cable is tough, which makes it resistant to physical damage. It can endure hits, cuts, and stress without impacting the wires inside.

(2). Resistant to extreme weather — It’s also created to withstand harsh climate condition. Rain, snow, or extreme temperatures, it can deal with it all without losing its effectiveness.

(3). Prevents electrical interference — Electrical interference can disrupt the flow of existing, but this cable is designed to avoid that. It makes sure a stable flow of electricity.

(4). Boosts safety from fires — Safety is another vital feature. The cable’s design helps to stop fires from distribution, keeping buildings and people safer.

(5). Supports heavy load capacity — Lastly, due to its robust construction, it can support heavy loads. It’s ideal for high-demand applications where regular cables might fail.

Please feel free to contact us if you have any questions.

Send Email

Place of Origin: Henan, China

Brand Name: Huadong

Standard: BS IEC ASTM DIN

Voltage: 0.6/1kV

Number of cores: 2 Core

Conductor Material: Copper

Insulation Material: XLPE

sectional area: 35mm²

Armouring material: Galvanized steel wire armoured

Operating temperature: 0°C – 90°C

Warranty: 100%quanlified

MOQ: 1000M

Price: Get within 12 hours

2 core 35 mm² SWA armoured cable is a cable with strong resistance to drawing and crushing, and it can adapt to any extreme environment. Steel wire armor has strong flexible strength and can be utilized for laying directly buried cables or basic threading pipes, general roads, tunnel construction, etc, while 2 core 35 mm² armoured cable has strong extrusion resistance and is appropriate for the overhead or vertical laying of short-circuit lines.

Adding a metal-clad armor protective layer to the cable can prolong the life span of the cable, enhance the anti-interference ability of the cable through shielding protection, strengthen the anti-corrosion ability of the cable, and stop mice from biting.

2 core 35 mm² SWA armoured cable have many application scenarios, as follows:

(1).Utilized in transformer stations, switching blocks, in electric power plants and industrial plants. Low voltage power cable for static application in ground, within and outside facilities, outdoor, in cable canals, in water, in conditions where cables are not exposed to heavier mechanical tension and tensile strain.

(2). To prevent the effects of external impact, the adhering semi-conductive layer extruded between conductor and insulation, together with concentric copper conductor, safeguards constraint of electric area and resistance to partial discharges.

(3). Because of its very low element of dielectric decrease, which remains continuous over its whole operating lifetime, and owing to excellent insulation property of XLPE-material, firmly longitudinally spliced with inner and external screen of semi-conductive material (extruded in one process), the cable has a high running dependability.

Managing and setting up armoured cables require a level of caution to uphold safety. Prior to setup, guarantee the cable is suitable for its intended use, considering factors like the environment, the nature of the application, and the cable’s rated temperature and voltage.During installation, prevent twisting or bending the cable beyond its minimal bending radius. Excessive bending can destroy the armour and compromise its effectiveness.

Remember that the ends of the metallic armour can be sharp. Handle with care to prevent injuries. Use of suitable protective gear, like gloves, can be highly advantageous in this regard.A routine visual inspection can also help spot potential issues early. Always check for signs of damage or exposed wires before working with armoured cables. Damaged cables should be repaired or replaced immediately.

Please feel free to contact us if you have any questions.

Send EmailOur vision is to become an internationally renowned brand in the field of cables; customer satisfaction, employee promotion, and corporate development are our service tenets; high standards, globalization, and building an international brand are our business philosophy.

Henan Huadong Cable Co., Ltd. was founded in 1999 which is a joint-stock national high-tech enterprise integrating scientific research, industry and trade. Huadong Cable is deeply integrated into the "Belt and Road" construction and exports to more than 130 countries around the world, including Europe, South America, North America, the Middle East, Africa, Asia, and Oceania.

Huadong Cable focuses on technology research and development which has 60 professional personnel with senior professional titles, and has more than 100 invention and utility model patents. Huadong has a team of experienced technical engineers to ensure the quality of cables.

Our main products : marine cables, power cables, overhead cables, fireproof cables, low-smoke halogen-free cables, rubber cables, high temperature resistant cables, instrument and control cables, solar cables and other products.

Export Countries

Technical Patents

Annual Productivity

Employees