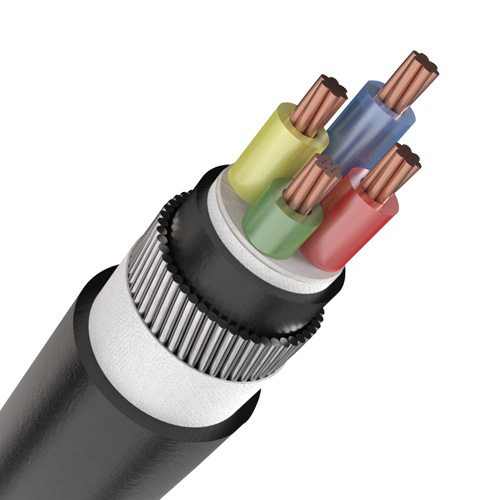

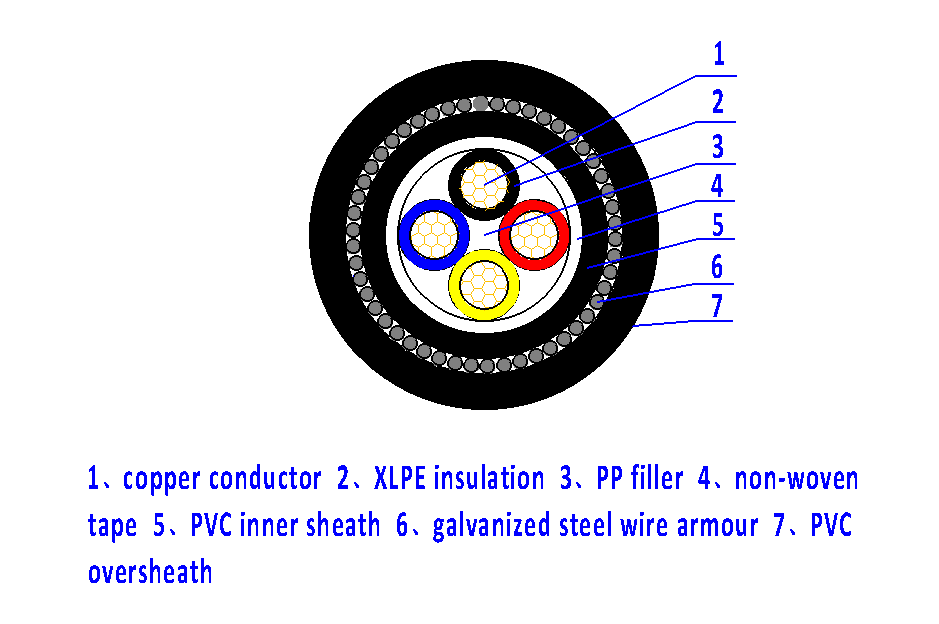

The construction of 4 core 240 mm² SWA armoured cables contains Plain Stranded Copper conductor, insulated with Cross-Linked Polyethylene, bedding and sheathing made from Polyvinyl Chloride (PVC).For single-core cable, the armouring beneath the sheath is usually Aluminium (AWA Cable). In cable with multiple cores, it is steel, SWA– Steel wire armour.SWA Cable matches both outside use and direct burial. The armour below the sheath also permits pulling loads because of increased strength.

We provide a comprehensive series of BASEC-approved 4 core 240 mm² SWA armoured cables, manufactured in accordance with a number of British, European and International standards including BS5467, BS6622, BS6724, BS7835, BS EN 50267, IEC 60502 and BS EN 60332-1-2 (for single core cables). Huadong Cables’ range of armoured cable is offered with a Copper (Cu) or Aluminium (Al) conductor and with a Polyvinyl Chloride (PVC) or Low Smoke Zero Halogen (LSZH) sheathing, LSZH sheathings are recommended for use in high density enclosed areas, and are obligatory in some social places.

Due to above 4 core 240 mm² SWA armoured cable structure,which has many advantages,as follow:

Without the use of electrical conduit, elbows, expensive offsets, or channel couplings, armoured cables offer the required protection and durability.Armour made of metal is resistant to corrosion and suitable for use in damp environments.

Interlocked armour, unlike conduit or even continuously welded armour, is flexible, ensuring that damage does not affect internal conductors. It is also easier to install in position where conduit would deal with complicated, close-spaced flex.Installation needs no specialized cutting or bending tools.

Please feel free to contact us if you have any questions.

Send Email

Place of Origin: Henan, China

Brand Name: HUADONG

Standard: BS IEC ASTM DIN

Voltage: 0.6/1kV

Number of cores: 4 Core

Conductor Material: Copper

Insulation Material: XLPE

sectional area: 240mm²

Armouring material: Galvanized steel wire armoured

Operating temperature: 0°C – 90°C

Warranty: 100%quanlified

MOQ: 100M

Price: Get within 12 hours

The purpose of 4 core 240 mm² SWA armoured cable is to enhance the cable’s mechanical strength and improve the anti-erosion ability. The commonly used armor materials are steel tape, steel wire, and aluminum tape. The steel tape and steel wire armor layer have high permeability and an excellent magnetic shielding impact, resisting low-frequency obstruction.It is a special cable designed for the area which is prone to mechanical damage and erosion.

4 core 240 mm² SWA armoured cable is made of difficult steel wire conductor placed with an insulation layer. Steel wire armoured cable is generally used in engineering, metallurgy, machinery manufacturing, construction and more. The mechanical protection layer of the armoured cable can be added to any structure of the cable to increase the mechanical strength of the cable and improve the anti-erosion chance, which appropriates for the bad environment, and the steel wire to protect the conductor and insulation.

Due to the 4 core 240 mm² SWA armoured cable’s feature,which have many application,as follow:

1. Oil and Gas Industry

The requiring conditions in the oil and gas sector require cables that can endure excessive temperatures, pressure, and exposure to chemicals. Armoured electrical cables, with their robust design, are well-suited for this industry, guaranteeing a reliable power supply in challenging environments such as offshore drilling rigs and oil refineries.

2. Renewable Energy Projects

The 4 core armoured cable play a crucial role in connecting renewable resource sources to the power grid. Whether it’s a solar farm or a wind energy project, these cables offer the necessary infrastructure to transfer the produced electricity efficiently and securely.

3. Commercial Buildings

Armoured cable are commonly employed in commercial buildings for their ability to provide a secure and reliable power distribution network. From office complexes to shopping malls, these cables guarantee a consistent power supply, contributing to the smooth functioning of various electrical systems.

4 core 240 mm² SWA armoured cable’s design features have mechanical protection, which discusses its typical use for exterior applications. The armour reduces any danger of pinching or damaging the cable, while the steel protects the armoured cable. SWA cables are heavy, which makes them remarkably challenging to bend; therefore they are most matched to underground cabling or fixed to outdoor walls using cable cleats.

Use Cable Cleats to attach the SWA cable to walls and structures. Cable cleats give a safe, secure match. Cleats may also be a choice for running cable along the sides of the building, rooftops or outbuildings. Cleats provide safety and security for surface mounting.

You must utilize Warning Tape for underground cable positioning. Utilize warning tape offers cables to be visible in case someone was to dig in the area. Always treat safety as critical when you lay cables. Precaution tape reduces the high risk of accidental severing.

Please feel free to contact us if you have any questions.

Send EmailOur vision is to become an internationally renowned brand in the field of cables; customer satisfaction, employee promotion, and corporate development are our service tenets; high standards, globalization, and building an international brand are our business philosophy.

Henan Huadong Cable Co., Ltd. was founded in 1999 which is a joint-stock national high-tech enterprise integrating scientific research, industry and trade. Huadong Cable is deeply integrated into the "Belt and Road" construction and exports to more than 130 countries around the world, including Europe, South America, North America, the Middle East, Africa, Asia, and Oceania.

Huadong Cable focuses on technology research and development which has 60 professional personnel with senior professional titles, and has more than 100 invention and utility model patents. Huadong has a team of experienced technical engineers to ensure the quality of cables.

Our main products : marine cables, power cables, overhead cables, fireproof cables, low-smoke halogen-free cables, rubber cables, high temperature resistant cables, instrument and control cables, solar cables and other products.

Export Countries

Technical Patents

Annual Productivity

Employees