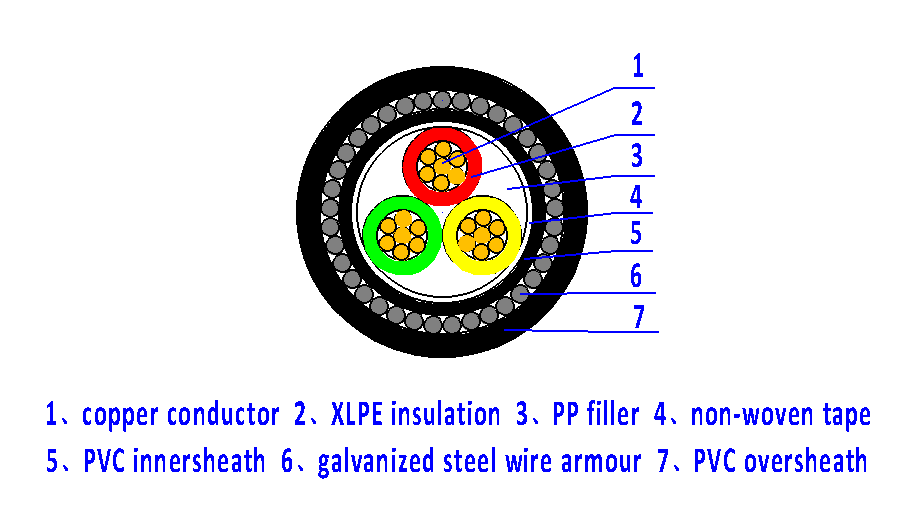

3 core 240 mm² SWA armoured cable are often described as steel wire armoured cables, SWA cable, mains power cable, single core power cable, and multi-core booklet armoured cable.The structure of our various kinds of armoured cable (US spelling armored cable) differs base on their intended application and may also include steel tapes, protective screens and materials matched especially to the installation conditions.

We provide a comprehensive series of BASEC-approved armoured cables, manufactured in accordance with a number of British, European and International standards including BS5467, BS6622, BS6724, BS7835, BS EN 50267, IEC 60502 and BS EN 60332-1-2 (for single core cables).

There are some of 3 core 240 mm² SWA armoured cable’s advantage in use,as follow:

armoured cable has added protective armour can resist stronger mechanical forces and prevent damage from exterior forces that helps protect the cable core. This is essential in position where there could be unintentional harm to the cable due to mechanical tension or effect. To put it in context, generally, armoured cables would be used when you require the cable to be buried directly underground for outdoor setup or in tubes. There may be instances where the ground is opened up again, and in the process, a shovel or mechanical excavator may hit the buried cable by accident. In this case, the armour would help protect the cable conductor core from being revealed easily and prevent electric shocks and disruptions in power distribution.

Please feel free to contact us if you have any questions.

Send Email

Place of Origin: Henan, China

Brand Name: Huadong

Standard: BS IEC ASTM DIN

Voltage: 0.6/1kV

Number of cores: 3 Core

Conductor Material: Copper

Insulation Material: XLPE

sectional area: 240mm²

Armouring material: Galvanized steel wire armoured

Operating temperature: 0°C – 90°C

Warranty: 100%quanlified

MOQ: 100M

Price: Get within 12 hours

The purpose of 3 core 240 mm² SWA armoured cable is to enhance the cable’s mechanical strength and improve the anti-erosion ability. The commonly used armor materials are steel tape, steel wire, and aluminum tape. The steel tape and steel wire armor layer have high permeability and an excellent magnetic shielding impact, resisting low-frequency obstruction.It is a special cable designed for the area which is prone to mechanical damage and erosion.

3 core Steel wire armored cable is made of difficult steel wire conductor placed with an insulation layer. Steel wire armoured cable is generally used in engineering, metallurgy, machinery manufacturing, construction and more. The mechanical protection layer of the armoured cable can be added to any structure of the cable to increase the mechanical strength of the cable and improve the anti-erosion chance, which appropriates for the bad environment, and the steel wire to protect the conductor and insulation.

Due to above 3 core 240 mm² SWA armoured cable Feature,which has many applications,as follow:

The defensive and resilient nature of armoured cables makes them highly demanded in a wide range of applications and industries. In construction and infrastructure advancement, these cables are used for power transmission in both underground and overhead installations. Their toughness and ability to endure severe environments also make them ideal for use in the utilities and renewable energy sector, including for power links in wind turbines and solar panels.

In the mining and marine industries, where environment conditions can be serious and unforeseeable, the use of armoured cables is prevalent due to their strength and stamina. Moreover, these cables are also used in heavy industries and manufacturing, where machinery and equipment require reliable and constant power supply.

When it comes to precisely what circumstances armoured cable should be used in, typically if the cable itself is going to be exposed to the weather and needs to be fully secured and water proof e.g. used externally then armoured cable should certainly be used.

Likewise if there is also a possibility that it could get damaged by effect force e.g. digging in the ground, pinching or crushing e.g. heavy weights being rolled over or pushed into the cable it needs to be able to withstand these forces and a standard residential grey electrical cable would merely not be up to the task and if it became destroyed would pose a huge danger and potential for injury.

In summary if a cable is to be operated externally, despite whether it’s buried or surface mounted or is going to be used in industrial locations around heavy machinery then armoured cable should always be used.

Please feel free to contact us if you have any questions.

Send EmailOur vision is to become an internationally renowned brand in the field of cables; customer satisfaction, employee promotion, and corporate development are our service tenets; high standards, globalization, and building an international brand are our business philosophy.

Henan Huadong Cable Co., Ltd. was founded in 1999 which is a joint-stock national high-tech enterprise integrating scientific research, industry and trade. Huadong Cable is deeply integrated into the "Belt and Road" construction and exports to more than 130 countries around the world, including Europe, South America, North America, the Middle East, Africa, Asia, and Oceania.

Huadong Cable focuses on technology research and development which has 60 professional personnel with senior professional titles, and has more than 100 invention and utility model patents. Huadong has a team of experienced technical engineers to ensure the quality of cables.

Our main products : marine cables, power cables, overhead cables, fireproof cables, low-smoke halogen-free cables, rubber cables, high temperature resistant cables, instrument and control cables, solar cables and other products.

Export Countries

Technical Patents

Annual Productivity

Employees